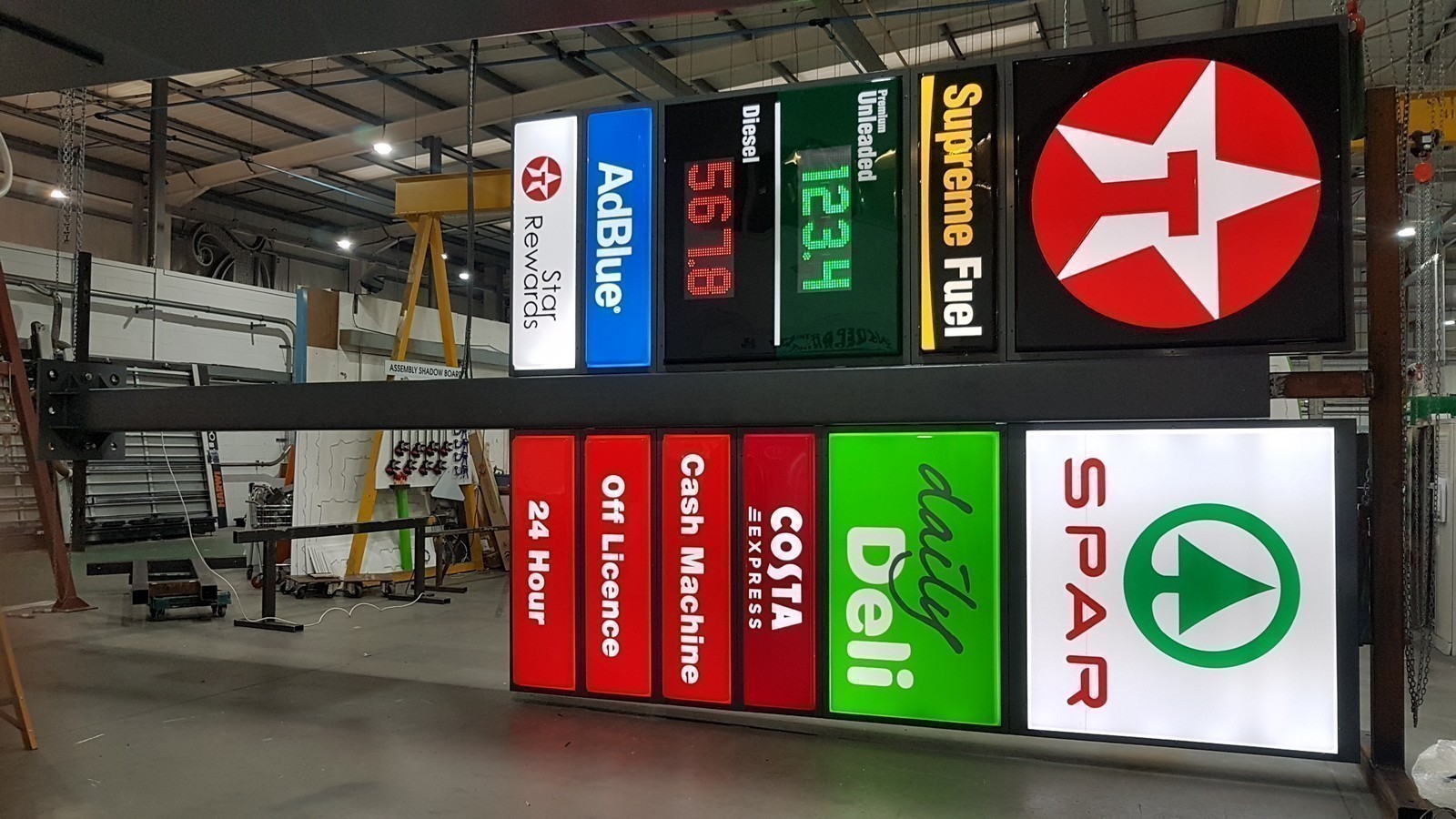

Following a competitive tender process we were awarded sole supplier status for the UK by leading petroleum giant Texaco.

Considered the ‘go to’ branding partner in the UK for PFS and New Energy brands, astley has been privileged enough to have supported this brand for over a decade now, being entrusted with the branding of their forecourts across the country.

With four strategically located UK sites, we offer true nationwide coverage and the resources to handle even the highest volumes. Our fully trained crews and precision logistical planning, driven by a seasoned project team, ensure every site is delivered on time, to spec, and without compromise. For brands with big visions and bold footprints, we’re the partner that makes it happen.