Investing in accreditations to maximise efficiencies and minimise risk

Astley was one of the first UK signmakers to understand the value of achieving BS EN 1090 for structural fabrication, identifying the need to provide this service in-house to keep costs down and retain quality control at all times. Our custom-built Gateshead site was designed with this key service in mind.

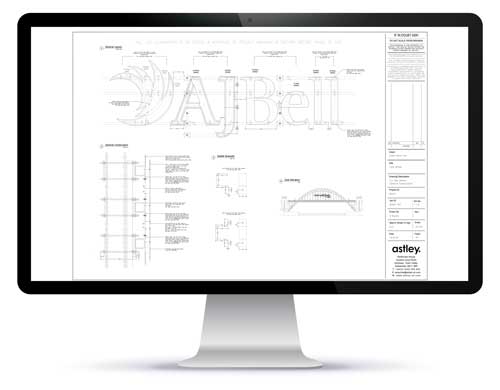

Now a legal requirement in the UK, BS EN 1090 is required for large structural steel work, and in sign making this could mean large building signage, built-up architectural lettering, freestanding totems and any other built-up brand messaging. This certification guarantees the product has been designed and manufactured using carefully governed and legislative processes in mind to ensure that when these products are installed, they will be safe and not put brands at risk by not performing.

We remain one of only a handful of signmakers that offer this service in-house, protecting the brands we work with by designing, manufacturing and installing structural assets that meet with H&S regulations. Using a partner that doesn’t hold this standard leaves brands open to risk of asset failure and hefty consequences.